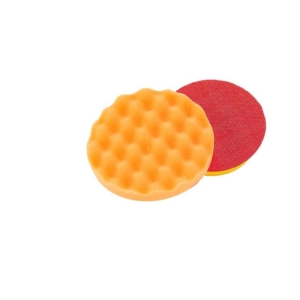

Description

- The highest-performing foam compounding pads

- Works with 3M™ Hookit™ for easy change-outs

- Diameters as small as 3” for accuracy in tight spaces or small areas

- Foam construction holds polish, prevents slinging for faster, cleaner results

- Part of the 3M™ Perfect-It™ Paint Finishing System for showroom grade finishes

The 3M™ Perfect-It™ Foam Compounding Pads are the highest-performing foam compounding pads for refining sand scratches, slow-speed polishing, denibbing and more. Foam face pattern provides more surface contact, holds compound better and reduces slinging. Doubled-sided pads work with 3M™ Quick Connect Adaptors on rotary polishers; double-side pads work with our Hookit™ system for easy change-outs.

For the highest performance at every step during auto body compounding, our 3M™ Perfect-It™ Foam Compounding Pads combine features that save time and improve results — for each job, and in your auto body operation. Pad face patterns are designed into the foam to hold more compound and limit slinging, as well as provide more contact with the surface for maximum efficiency. Choose a 3-, 6- or 8-inch diameter pad for a variety of specific applications including working with cured, hard or medium finish paint, denibbing, scratch removal and refining P1200 or finer sand scratches even in confined spaces.

Another Perfect-It™ Top Performer

These foam pads are developed as part of the 3M™ Perfect-It™ Paint Finishing System to keep pace with evolving paint and clear coat technologies. Foam pads are generally less aggressive and produce a finer finish than wool pads, ideal for the critical compounding stages of paint refinishing. They can normally operate at higher RPMs, relying on a combination of cutting and heat buildup to slightly melt the surface coating and remove fine scratches and swirl marks. 3M™ Perfect-It™ Foam Compounding Pads are best used in conjunction with Perfect-It™ Rubbing Compound and are quickly attached to rotary and random orbital tool.